Technologies

Planar Doppler Velocimetry

Planar Doppler Velocimtery (PDV) is capable of measuring instantaneous, three-dimensional velocity vectors of moving particles or solid material in a laser light sheet everywhere in the field of view. The PDV technique is applicable to facilities of any size in which adequate optical access is available and light-scattering aerosols can be added to the flow. Single-particle discrimination is not necessary so that measurements can be made at any range where smoke or aerosol scattering from laser light can be photographically recorded. These features make PDV uniquely attractive for applications in very large scale flows.

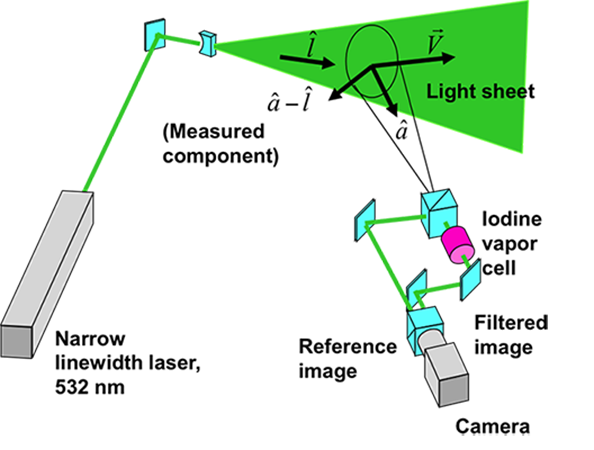

The PDV concept is based on the sensitive frequency discrimination that can be obtained by viewing scattered laser light from aerosols in the flow through an optical cell containing iodine vapor. The laser frequency is tuned to the 50% transmission edge of an iodine absorption feature, and the bandwidth of the laser light is narrow compared to the spectral range of the absorption edge, causing the light intensities transmitted by the filter to be sensitive to frequency. In its full implementation, pairs of filtered and unfiltered images are obtained from each laser pulse for each of three directions. The filtered images from each direction are normalized by the unfiltered images to eliminate the variations in intensity not related to Doppler effects. The normalized intensity levels in the three final images become images of three separate and instantaneous velocity field components everywhere in the field of view. Their combination provides a complete 3-D velocity vector field.

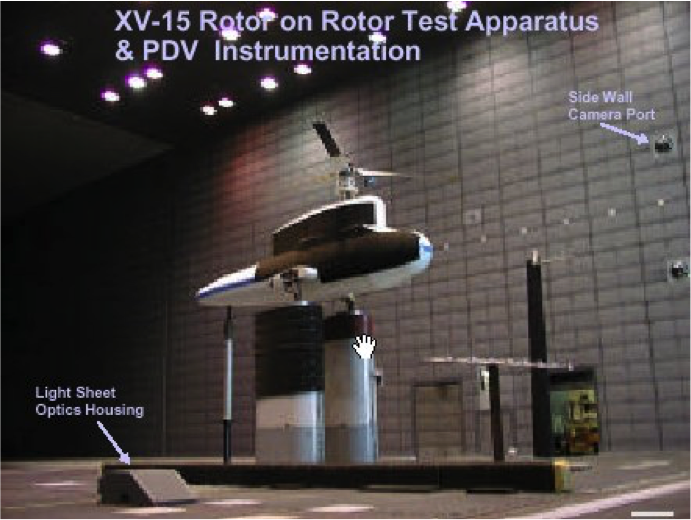

At NASA Ames Research Center, the PDV technique has been developed and shown to be capable of resolving velocities as low as 2 m/s from a single laser pulse and to be applicable at ranges exceeding 40 meters. These capabilities, in addition to the minimal requirements of PDV on the optical features of the aerosols in the flow, make it particularly attractive as a means of measuring 3 D velocity vector fields in time dependent flows in large scale wind tunnel facilities. In the past year, a high-quality, 3-camera, PDV system has been assembled and installed in the Ames 80×120 ft. wind tunnel to allow flow field measurements between the moving rotor blades of a full-scale rotor.

Successful measurements of 3-D velocity vector fields have been obtained for the first time at optical ranges exceeding 20 meters. The results show the instantaneous location and strength of blade tip vortices and the 3-D velocity vectors in the wake of each passing blade.

Foreseeable applications of PDV other than large scale wind tunnel measurements might include velocity field measurements in the open air of (a) shipboard air currents affecting aircraft landings, (b) air current disturbances from smoke stack emissions, (c) flow shedding around buildings, bridges, and large structures, (d) flow entrained behind ground-based vehicles either passing through a stationary smoke cloud or from smoke released from the vehicle, and (e) flight line and landing zone disturbances caused by jet exhaust and helicopter downwash – to name a few. In some of these examples, the use of three camera views may not always be practical but unprecedented flow field information can be obtained from the measurement of a single velocity component, using just one remote camera system.

PDV can also be applied to measurements of the motion of solid objects whenever there are unique advantages to the use of localized laser targeting and the spatial discrimination that is provided by velocity field images. Examples might include the individual flight paths and spin or tumbling velocities of multiple targets, the local velocities of moving machinery parts, and the motion of biological targets, to name a few. In the case of measurements on solid objects where the path of the motion is known, only a single camera system is necessary to obtain the complete velocity along the trajectory and the laser illumination can be volumetric, rather that a light sheet.